Ship Lengthening / Conversions

When newbuilds are not an option, Ship Upgrades are solution.

Our engineers have gained an extensive experience in supporting the Owner's aspirations of improving efficiency of their fleet by adapting their vessels to a constant changes on maritime shipping market.

Sometimes it's the lengthening of the ship that improves the efficiency of the vessel, sometimes vessels are to be adapted for a different type of cargo then originally being built for, but what is common for these interventions is that they prolong the commercial life of ships...and we're happy to contribute in achieving this goal.

References

CLASS: DnVGL

Description: Barge upgrade with sponsoons, additional Floating towers & existing Deckhouse raisng for 10m

Year: 2019

SRS Scope of Work:

- Class. drawings (Hull/Machinnery/Outfitting)

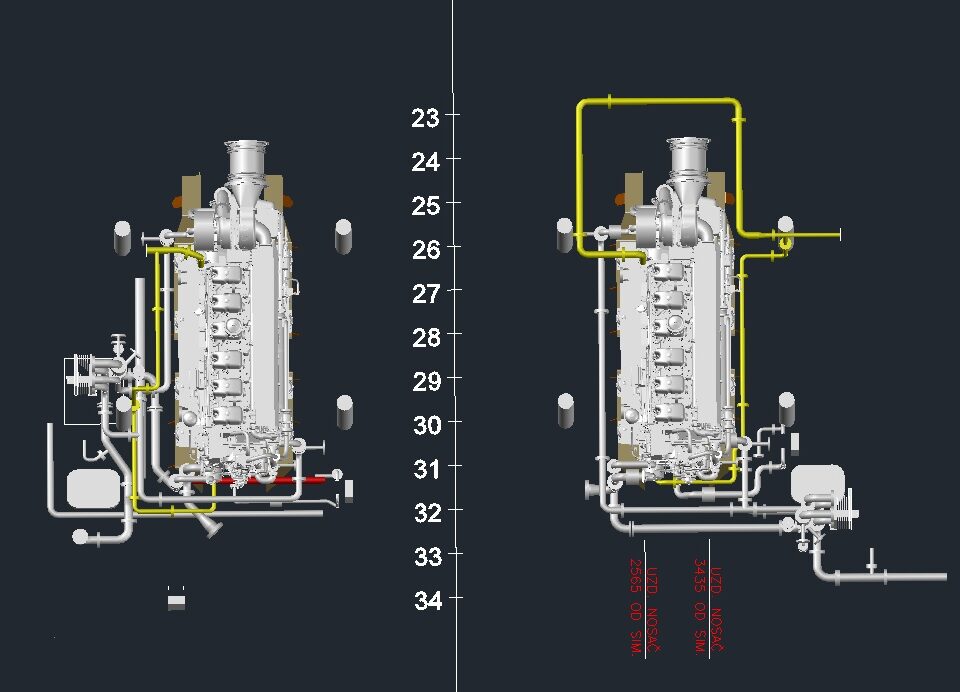

CLASS: HRB

Year: 2018

SRS Scope of Work:

- Main engine supporting structure

- E.R systems diagrams (New & Updated)

- Workshop Drawings: Piping Installation & Spool drawings

Type: Multipurpose offshore vessel

Class.: DnV

Year: 2012

SRS Scope of work:

Basic Design

- Class. Drawings of Hull lengthening (17m) & Rule calculations

- Class. drawings & FEM calculations for deck foundations (and below deck strengthening) for installation of 250t Stern A-Frame

- Class. drawings & FEM calculations for deck foundations (and below deck strengthening) for installation of 2000t Cable laying carousel

- Class. drawings & FEM Calculation for various cable laying Deck equipment

- Machinery diagram update

Green Technology retrofits

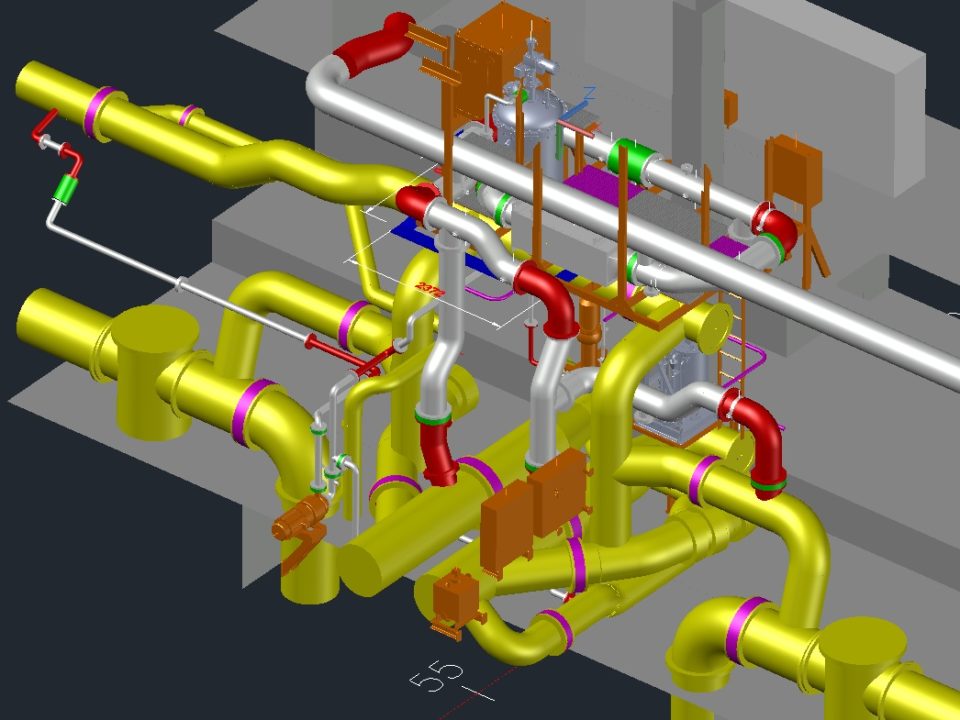

Since the IMO requirments regarding SOx/NOx emissions and ballast discharge requirements (D-2) have come into force, our Machinery engineers have proven their skills in many BWTS Retrofits (Alfa Laval, De Nora, Optimarine, Headway, Sunrui), EGCS Retrofits (Langh Tech, Saacke, CleanMarine), and SCR Retrofits.

SRS may provide Retrofit documentation for installations on 3 levels:

1. Feasibility study

- Evaluation of available resources (Electric power, pump & Stripping eductor performance, available space)

- Reccomendation of BWTS/EGCS/SCR system (in case the Owner has not decided yet)

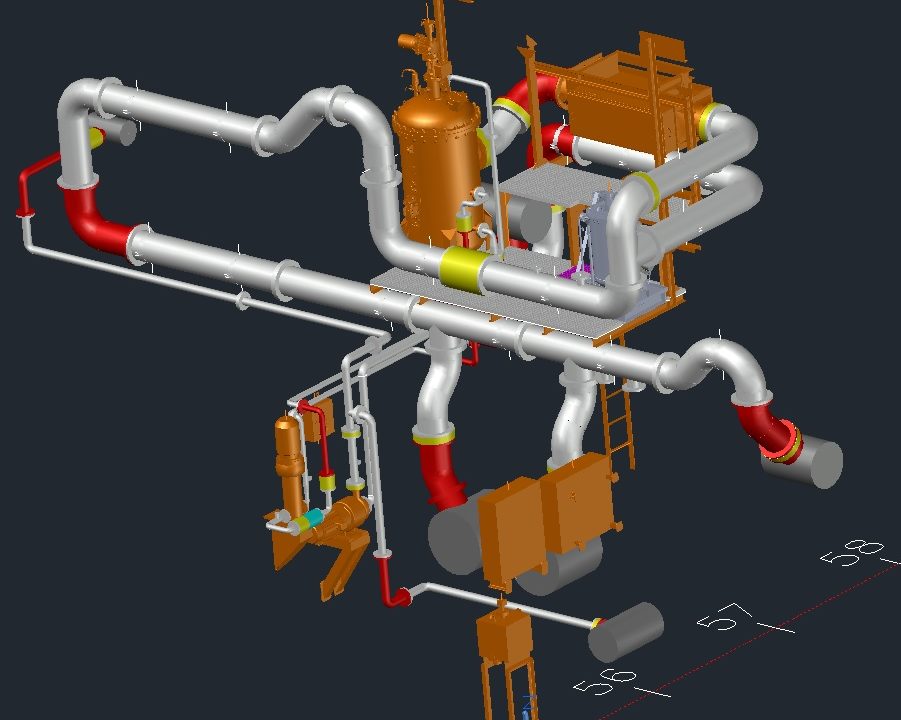

- 3D Component and Piping Layout

- Onboard Survey (with 3D Laser Scanning as an option)

2. Classification drawings/diagrams

- Preparation of BWTS/EGCS/SCR diagram

- Alteration of existing Class. drawings as neccessary

- Neccesssary structural drawings (i.e. deckhouses, platforms, foundations)

- Ballast Water Management Plan preparation

- Valve list

- Yard specification

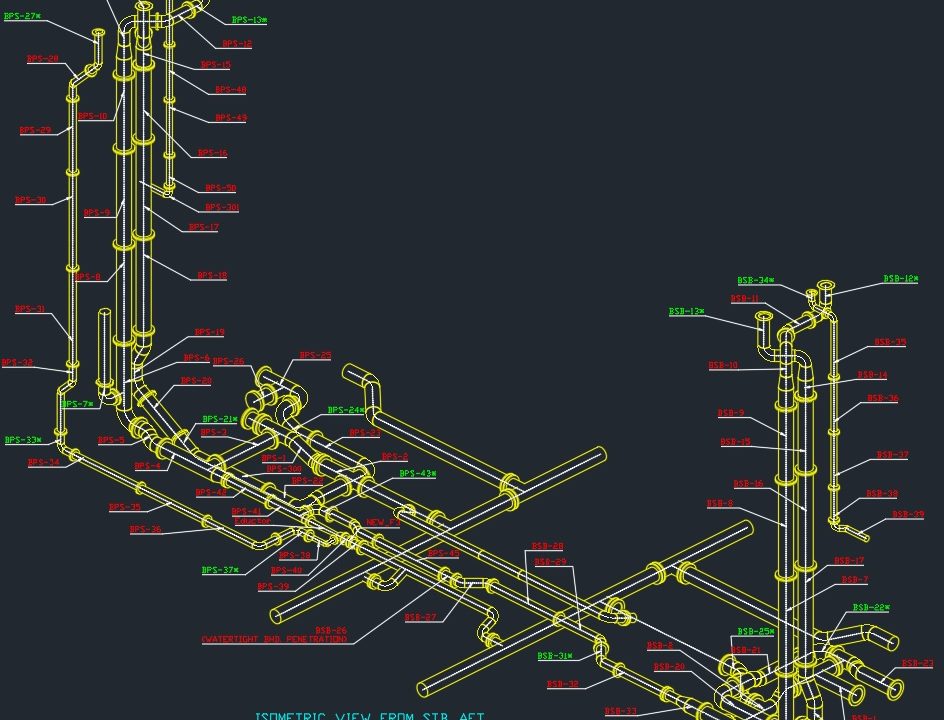

3. Workshop documentation

- Installation drawings

- ISO Spool drawings

- Bill of material

Feasibility study is the most important phase of any Retrofit installation because it gives you an answer to a very important question: Is your onboard equipment and resources adequate to perform the task together with new equipment that is to be installed? If they're not, unexpected costs and probable delays will occur in the most inconvenient moment... while in Yard.

In order to answer above questions, our engineers are performing Flow analysis with new equipment included, and compare them with available resources.

It is to be noted that for all of above mentioned Retrofit installations, 3D Laser Scanning is an option (not an imperative) in order to provide best implementation results.

References

CLASS: LR

Unit: AlfaLaval Pure Ballast 3.2

Technology: Filter + UV

Rated capacity: 2×500 m3/h

Year: 2021

SRS Scope of Work:

- Workshop drawings (piping & outfitting)

CLASS: DnV

Unit: Headway OceanGuard BWMS HMT-800

Technology: Filter+Electro-Catalysis

Rated capacity: 1040 m3/h

Year: 2022

SRS Scope of Work:

- 3D scan of engine room on board the vessel

- Feasibility study with 3D piping and layout

- Class drawings (new & update of existing)

- Workshop drawings (piping & outfitting)

CLASS: DnV

Unit: Headway OceanGuard BWMS HMT-800

Technology: Filter+Electro-Catalysis

Rated capacity: 1040 m3/h

Year: 2021

SRS Scope of Work:

- 3D scan of engine room on board the vessel

- Feasibility study with 3D piping and layout

- Class drawings (new & update of existing)

- Workshop drawings (piping & outfitting)